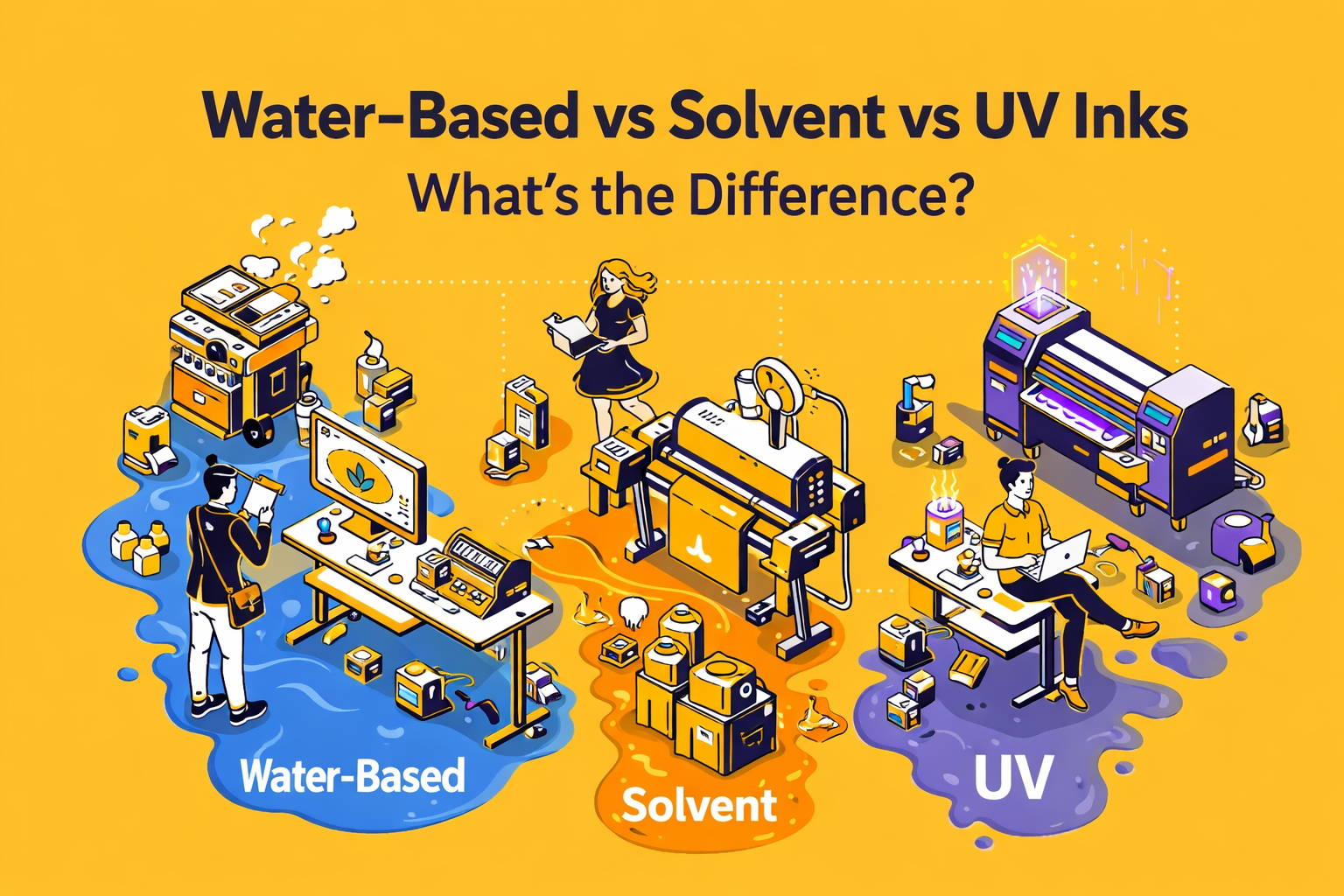

What Is the Difference Between Water-Based, Solvent, and UV Inks?

Choosing the right ink system is one of the most important decisions a commercial print business can make. In Australia, that choice affects far more than print quality alone. It directly impacts energy consumption, curing reliability, workplace safety, compliance requirements, durability, and long-term consumable costs.

Yet many printers continue using the same ink system simply because it is familiar.

This article explains the real differences between water-based, solvent, and UV inks, where each performs best, and the hidden costs that are often overlooked when selecting print consumables.

How Water-Based, Solvent, and UV Inks Work

To understand performance, cost, and suitability, it’s essential to understand how each ink system cures.

Water-Based Inks

Water-based inks use water as the primary carrier for pigment. After printing, the water must evaporate through heat and airflow, allowing the ink to bond to the substrate.

In Australia, water-based inks are commonly used for :

Textile printing

Paper and cardboard applications

Short-run packaging

Environments where low odour and safer handling are important

They are often chosen for their sustainability perception and lower solvent content. Water-based systems typically require less specialised ventilation and are easier to operate in enclosed spaces.

Solvent Inks

Solvent inks use chemical solvents to carry pigment into the surface of the media. As the solvent evaporates, the ink effectively bites into the substrate, creating strong adhesion.

They are widely used across Australia for:

Outdoor signage

Vinyl

Banners

Vehicle graphics

Applications that require long-term outdoor durability

The main advantage of solvent inks is their reliability on difficult or non-porous substrates, combined with excellent resistance to weather and UV exposure. For many signage businesses, solvent systems have been a dependable workhorse for years.

UV Inks

UV inks cure instantly when exposed to ultraviolet light. Unlike water-based or solvent inks, there is no evaporation process. The ink solidifies immediately on the surface when exposed to the UV source.

UV inks are increasingly used in Australia for:

Signage

Packaging

Industrial printing

Displays

Mixed-substrate applications

Instant curing offers several clear advantages. Prints can be handled immediately, production speeds increase, and curing is not affected by humidity. Modern LED UV systems also consume significantly less energy than traditional heat-based drying methods.

The Hidden Cost Many Printers Overlook

Ink price alone does not reflect the true cost of production.

Real consumable cost includes electricity for drying or curing, failed prints and reprints, operator time, cleaning and maintenance fluids, and downtime caused by adhesion or curing issues.

Many printers discover that switching to a more suitable ink system reduces waste, shortens turnaround times, and improves margins—even if the ink itself costs more per litre.

Ink selection should always be treated as a production decision, not just a purchasing one.

How to Choose the Right Ink for Your Business

The most effective way to choose an ink system is to assess your operation honestly.

Consider the substrates you print most often, your required turnaround times, electricity costs, working environment, and whether flexibility or specialisation matters more to your business.

When the ink system matches the way you actually produce work, consistency improves and costs become easier to control.

Final Thoughts

Water-based, solvent, and UV inks all play an important role in modern print production. The key is understanding how they differ and selecting the system that supports your workflow, cost structure, and long-term goals.

For Australian printers, factors such as humidity, energy pricing, and compliance make this decision even more critical.

If you are unsure whether your current ink system is operating as efficiently as it could, speaking with a specialist can uncover opportunities to reduce waste, improve consistency, and lower total production costs.

For guidance on ink selection, curing, and long-term consumable performance, the team at Kissel+Wolf Australia can help assess your setup and recommend solutions aligned with your applications. Contact us by clicking on this link.