Modern Screen Printing Equipment: Strengthening Every Step of the Screen Room Process

A high-performing screen printing operation is built in the screen room. Every stage, from stretching to reclaiming influences print quality, efficiency, durability and long-term profitability. Modern equipment does more than improve consistency. It reduces variables, protects margins and allows print businesses to operate with greater confidence and control.

Below is a step-by-step look at how each stage benefits from modern equipment and why it matters for Australian printers.

1. Screen Stretching: The Foundation

Consistent mesh tension is critical for sharp detail, clean snap-off and stable registration.

Modern stretching systems ensure even, repeatable tension across frames, reducing the small distortions that often cause on-press adjustments.

Benefits of controlled stretching:

Stable multi-colour registration

Cleaner edges and sharper print definition

Reduced press-side troubleshooting

Longer mesh life

Improved repeatability for recurring jobs

High, even tension reduces distortion and improves ink release, which directly impacts print clarity and production speed.

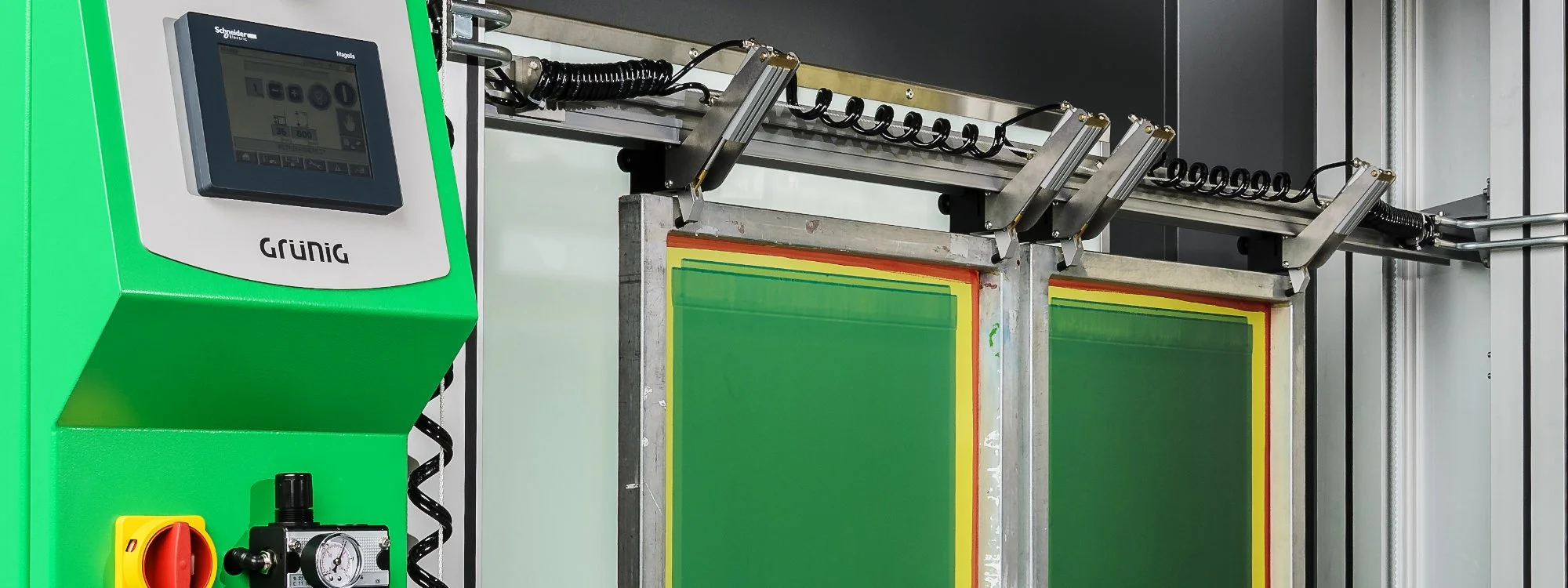

G-STRETCH 270

An example of an automated stretching table from Grunig manufactured in Switzerland.

2. Coating & Exposure: Durable Stencils

Exposure accuracy determines how well a stencil performs under production pressure. Modern exposure units provide stable light output and precise timing, ensuring emulsions cure evenly and predictably.

Benefits of accurate exposure systems:

Stronger stencils with better durability

Reduced stencil breakdown mid-run

Improved fine detail and halftone reproduction

Fewer costly screen remakes

When exposure is controlled, setup becomes faster and production interruptions are reduced.

3. Washout: Image Development

The washout stage determines how accurately the stencil develops. Modern washout booths provide consistent water pressure and improved drainage and filtering systems, protecting mesh integrity and stencil quality.

Benefits of structured washout systems:

Reduced mesh damage

Fewer pinholes and stencil defects

Faster, more predictable turnaround

Lower water and chemical waste

Improved screen longevity

A controlled washout process reduces hidden variables that can compromise print performance later on press.

4. Ink Performance: Results on Press

Even perfectly prepared screens rely on consistent ink behaviour.

High-performance ink systems deliver predictable flow, adhesion and opacity across textiles, industrial substrates and specialty applications.

Benefits of premium ink systems:

Reliable colour strength and vibrancy

Strong adhesion across challenging substrates

Reduced press-side adjustments

Improved wash durability

Greater confidence in repeat jobs

Consistent ink performance reduces setup time and protects brand colour accuracy.

Ink Systems for Every Substrate

5. Reclaiming: Protecting Screen Life

Reclaiming is about restoring screens to a known starting point, not simply cleaning them.

Structured reclaiming processes and appropriate chemistry protect mesh fibres and prepare screens for consistent re-coating.

Benefits of controlled reclaiming:

Extended screen lifespan

Improved emulsion adhesion

Reduced ghost images and staining

Lower chemical overuse

Greater repeatability between production cycles

A reliable reclaiming process reduces screen degradation and protects long-term value.

The Bigger Picture: Why Modern Screen Equipment Matters

When every step in the screen room is supported by modern equipment, the benefits compound.

Upgrading the screen room delivers:

Greater operational control

Reduced waste and rework

Faster job turnaround

Lower long-term consumable costs

Improved staff efficiency

Modern screen printing equipment is an upgrade in process reliability, performance and competitiveness.

At Kissel+Wolf, we support Australian printers with complete screen room solutions that strengthen every stage of production.

Visit our website to learn more or contact us to enquire about solutions that fit you using the contact form below.