Screen Washing Systems

Streamline your screen reclaiming and preparation with our automated washing solutions. Built for efficiency and precision, these systems handle washing, developing, and decoating processes with minimal water use and maximum consistency, helping you maintain clean, production-ready screens.

Grunig G-Wash 104

Screen Reclaiming – All Screen Types

Compact automatic screen washing unit offering efficient, programmable cleaning with a plug-and-play setup, ideal for solvent-based applications in screen printing environments.

For screens up to 1400 × 1500 mm (55 × 59 in)

“PLUG & WASH” design — unpack, set up, and start

Compact, low-maintenance, and easy to use

Programmable automatic washing cycles

ATEX-compliant for solvents with flash point >55°C

Grunig G-WASH 106

Automatic screen developing system with programmable pressure and spray control, designed for consistent, high-quality results in a compact, user-friendly format.

Screen Developing – All Screen Types

Maximum screen format: 1400 × 1800 mm

Electronically adjustable washing pressure from 5–12 bar (optional up to 20 bar)

Touchscreen interface with up to 50 cycles

Individual switchable nozzle bars for squeegee and print sides

Compact, stainless steel V2A construction with front-loading

Grunig G-WASH 112

Automatic screen decoating and degreasing system featuring plug-and-play setup, touchscreen control, and closed-loop water recycling—ideal for high-efficiency screen processing.

Screen Decoating – All Screen Types

Maximum screen size: 1400 × 1500 mm

“PLUG & STRIP” setup—unpack, connect, and start

Touchscreen interface with 50 cycles

Closed stainless steel chamber

Integrated water recycling reduces consumption up to 90%

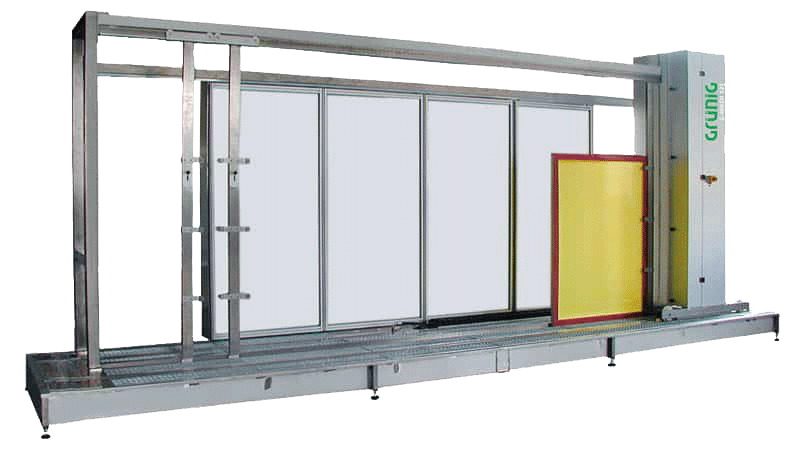

Grunig G-WASH 125

XL Reclaim System – Large Format Screens

Modular open-frame washing system engineered for large-format screens, offering programmable automation, high-pressure options, and seamless integration of developing, degreasing, and decoating processes.

Maximum screen format: 4000 × 10000 mm (157 × 394 in)

Open system design allows front or side loading

Modular configuration supports developing, degreasing, and decoating

Oscillating V2A stainless steel nozzles ensure gentle, efficient processing

Programmable control tower with up to 9 customisable programs

Grunig G-WASH 130

Screen Reclaiming – Small to Mid-Size Screens

Modular in-line system for automatic washing, decoating, and developing of screens up to 1 × 1.2 m, featuring closed-loop water recycling and ATEX-compliant design.

Handles screen formats up to 1 × 1.2 m

Modular design allows configuration for washing, decoating, and developing

Closed-loop water system with coarse and bag filters for reduced consumption

Constructed from high-quality chromium steel with innovative nozzle system

Designed for cleaning agents with flash point >55°C; ATEX-compliant construction

Grunig G-WASH 170XS-DUO

In-line Reclaim System - Small to Mid-Size

High-output dual-lane in-line washing system designed for automated, modular screen processing. It offers doubled throughput, programmable control, and efficient chemical management for industrial-scale screen printing operations.

Maximum screen format: 1400 × 1500 mm

Dual parallel washing lines for simultaneous screen processing

Modular design configurable as 2/3 chamber system

Supports washing, rinsing, decoating, and drying modules

Closed stainless steel V2A chamber with ATEX-compliant construction

Touchscreen interface with individually programmable washing cycles

Grünig Recyclean system reduces fresh water consumption

Removable nozzle units for simplified maintenance

Compatible with magazine feeders, dryers, and CtS integration

Designed for cleaning agents with flash point >55°C

Grunig G-Wash 034

Recycling System for Grunig Washing Systems

Automatic cleaning of various liquids

Efficient mechanical separation of liquids and solid matters based on inclined filtering technique

Enhanced economic efficiency and improved eco-balance by prolonging the service durability of process liquids

Can be easily connected to manual or automatic cleaning systems

Rugged and high-quality stainless steel construction

Grunig G-Wash 040XS

Inclined Chemical Filter for Grunig Washing Systems

Cleaning of liquids in a closed-circuit system (Flashpoint >55°C / >131°F)

Very efficient cleaning based on inclined filtering technique

Simple and safe IN-HOUSE cleaning of liquids

Can be connected to the most Grunig G-WASH machines

Rugged and high-quality construction of stainless steel V2A

Let’s work together

Let our experts analyse your current workflow and recommend the perfect print solution.