Screen Printing Basics: Everything You Need to Set Up Your Screen

Thinking of getting into screen printing or upgrading your current setup?

Whether you’re printing textiles, signage, or industrial materials, having the right consumables and equipment is critical to consistent, high-quality results. This guide walks you through the essential tools and materials needed to set up your screen printing workflow—backed by Kissel+Wolf Australia’s trusted product range.

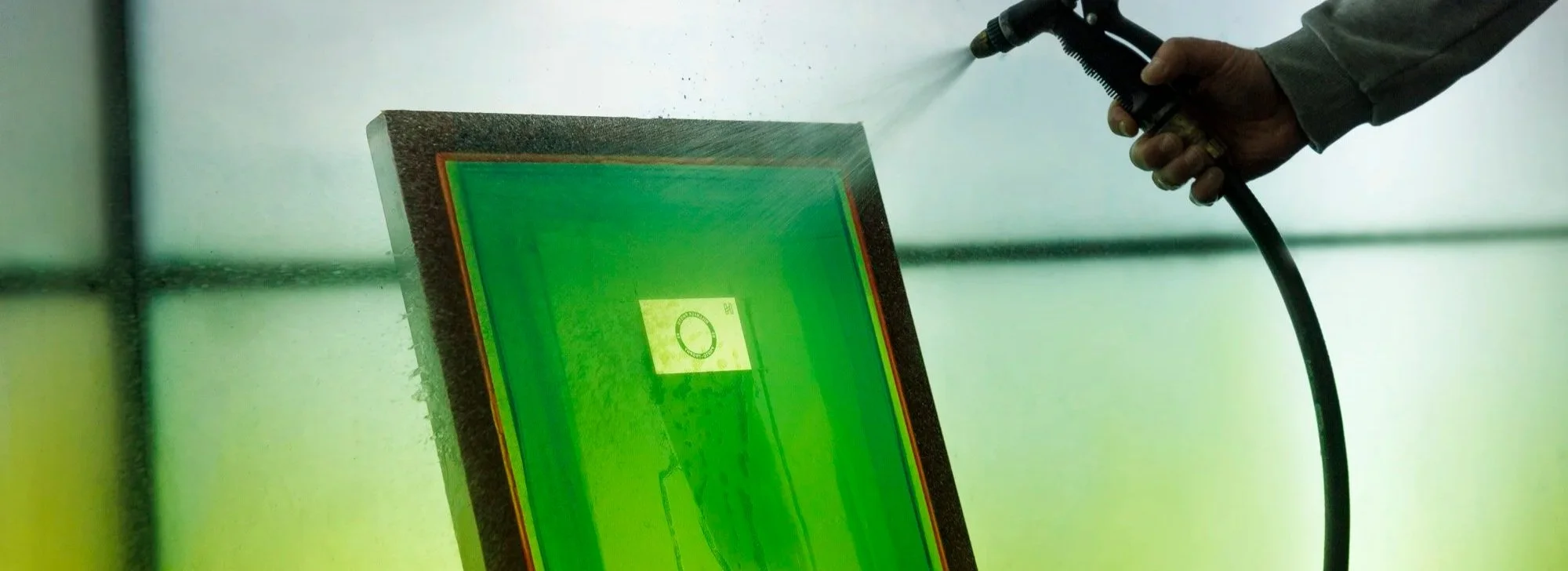

A Kissel+Wolf Screen Setup being washed out

1. Screens & Mesh

What you need:

Screens are the backbone of your setup. Depending on the job, you’ll need different mesh counts and frame types.

Kissel+Wolf Solutions:

Pre-Stretched Frames – Ready to use and available in various mesh counts.

Screen Stretching Services – We custom-stretch frames for your specific needs.

2. Emulsion or Capillary Film

What you need:

Emulsion is what allows your artwork to transfer onto the screen. Choose based on your ink type and exposure unit.

Kissel+Wolf Recommendations:

Ulano QXO & LX660 Emulsions – Ideal for both plastisol and water-based inks.

KIWO® Poly-Plus S – Reliable for solvent and UV inks.

Capillary Film – Perfect for printers seeking a faster, cleaner application.

3. Screen Coating & Drying

What you need:

A scoop coater ensures a smooth, even emulsion layer. After coating, screens need to be dried in a dust-free environment.

Kissel+Wolf Solutions:

Aluminium Scoop Coaters – Durable and easy to clean.

4. Exposure

What you need:

Once coated, your screen is exposed to UV light to harden the emulsion and create your stencil.

Kissel+Wolf Recommendations:

LED UV Exposure Units – Available in multiple sizes with vacuum contact.

5. Washout Booths & Cleaning Chemicals

What you need:

After exposure, wash out your screen to reveal your stencil. Regular screen reclaiming is essential for reuse.

Kissel+Wolf Essentials:

Washout Booths – Industrial-grade and ergonomic.

PREGASOL EP3 Stencil Remover – Fast and eco-friendly.

PREGAN Paste & Anti-Ghost Products – Remove stubborn ink stains and emulsion residue.

6. Inks & Additives

What you need:

Choose your ink based on your substrate and curing setup.

Kissel+Wolf Offers:

Avient Wilflex Inks – Industry-leading plastisol inks, including low-cure options.

Marabu Inks – Ideal for graphic and industrial screen printing.

Ink Additives – Tweak viscosity, cure speed, and adhesion with our range of trusted additives.

7. Squeegees & Holders

What you need:

The right squeegee ensures a clean, even print. Choose the right durometer (hardness) and blade style for your print type.

Available at Kissel+Wolf:

Triple Durometer Squeegee Blades

Aluminium Squeegee Holders

Squeegee Sharpeners – Keep your edge consistent for repeat jobs.

8. Curing Equipment

What you need:

Proper curing is essential to ink adhesion and wash resistance.

Kissel+Wolf Range:

Flash Dryers & Conveyor Dryers – Suitable for every production scale.

Low-Cure Ink Options – Save energy while maintaining print durability.

9. Reclaiming & Maintenance

What you need:

Keeping your screens clean extends their life and ensures top-tier prints.

Kissel+Wolf Recommendations:

PREGAN® Cleaning Products – Designed for safe and effective emulsion and ink removal.

Eco-Friendly Alternatives – Ask us about our safer chemical solutions.

✅ Ready to Build Your Screen Printing Setup?

At Kissel+Wolf Australia, we supply everything you need to succeed in screen printing—from beginner setups to advanced industrial workflows. Our expert team is here to help you choose the right consumables and equipment tailored to your business.