Digital Cutting Tables

Eliminate bottlenecks, reduce waste, and scale your production with cutting edge digital finishing solutions from Kissel+Wolf Australia.

iECHO PK Automatic Cutting System

Transforming Ideas into Reality

The iECHO PK is a compact, intelligent cutting system designed for ultra-short run and on-demand sheet or roll cutting. Ideal for label work, packaging samples, signage and more, it combines high-speed automation with precision accuracy in a user-friendly format.

Automatic Sheet/Roll Feeding System

CCD Camera Positioning System

Advanced 6-axis High-Speed Motion Control System

Cutting Area up to 1200 × 900 mm

Cutting Thickness up to 10 mm

iECHO BK4 High-Speed Digital Cutting System

Unlock New Possibilities

Engineered for speed and adaptability, the iECHO BK4 is built to handle high-volume production across multiple industries. With modular tooling and advanced automation, it delivers accurate cutting, creasing, and perforation on a wide range of materials.

Ultra-High Strength Integrated Frame

CCD Camera Positioning System

Diversified Cutting Modules

Intelligent Conveyor System

Several Material Unwinding Devices

iECHO TK4S Large Format Digital Cutting System

Expand Your Business

The iECHO TK4S is a high-performance large-format cutting solution built for signage, packaging, POP displays, and industrial sheet materials. Its powerful dual-beam configuration and advanced automation make it ideal for demanding production environments.

Aviation Aluminum Honeycomb Panel

CCD Camera Positioning System

Customisable Cutting Area up to 5500 × 3200 mm

High Productivity Dual Beam Cutting Capacity

Automatic Board Handling System

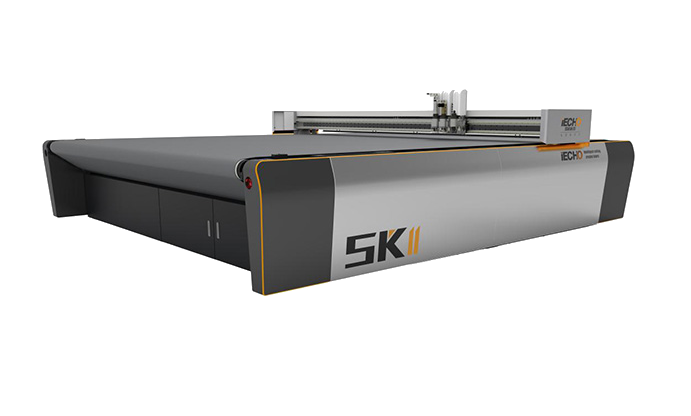

iECHO SK II The Ultimate Digital Cutting System

Outperform Your Competition

The SK II Series combines cutting-edge magnetic-driven technology with incredible speed and intelligence. Built for flexible materials across industries like fashion, automotive, and packaging, it offers unmatched performance and precision.

Magnetic Driven Technology

Cutting Speed of up to 2,000 m/sec

Intelligent Table Compensation

Cloud Service

Automatic Nesting Module

iECHO VK The Ultimate Digital Cutting System

Outperform Your Competition

The iECHO VK is a high-speed flatbed cutter with smart automation features and magnetic drive technology. Ideal for packaging, soft signage, and industrial prototyping, it offers precise, high-speed cutting and streamlined workflow integration.

Magnetic Driven Technology

Cutting Speed of up to 2,000 m/sec

Intelligent Table Compensation

Cloud Service

Automatic Nesting Module

Solutions Showcase

From complex packaging prototypes to high-volume production runs, iECHO systems tackle the challenges that keep production managers awake at night:

Material Versatility Challenges Solved: Handle any substrate from delicate papers to rigid plastics without production line reconfiguration

Quality Consistency Pain Points Eliminated: Achieve identical precision across thousands of pieces, ending customer complaints

Setup Time Bottlenecks Broken: Transition between completely different jobs in minutes, not hours

Production Flexibility Maximised: Respond to rush orders and last-minute changes without disrupting scheduled work

Struggling with slow turnaround times?

Our digital cutting tables boost efficiency, automate workflows, and handle complex jobs with ease—reducing manual labor and increasing output.

Overcome Your Toughest Production Challenges

Breaking Through Production Bottlenecks

The Challenge: Manual finishing processes creating costly delays and inconsistent results

Our Solution: Automated digital cutting systems that process materials 3-5× faster while maintaining precision across runs of any size

The Challenge: Difficult economic justification for short-run jobs that tie up resources

Conquering Short-Run Profitability

Our Solution: Quick-setup digital cutters that make even single-unit runs profitable, eliminating expensive die costs

The Challenge: Traditional cutting methods wasting expensive materials and inflating costs

Eliminating Material Waste

Our Solution: Precision digital cutting with optimized nesting that reduces waste by up to 30%

The Challenge: Finding and retaining skilled finishing operators in a tight labor market

Winning the Labor Shortage Battle

Our Solution: User-friendly automation that reduces labor dependencies while maximising output

Featured Problem-Solvers

Versatility That Pays Off

PK Small Cutting System

Automation implementation with intuitive intelligent workflow

BK4 Cutting Solution

Solves high-volume deadlines with industry-leading throughput speeds

TK4S Large Scale

Conquers large-format limitations with extended cutting area

SKII High Production

Masters the most demanding applications with ultimate control

Ready to Solve Your Production Challenges? Contact us.

Let our solutions experts analyse your current workflow and recommend the perfect digital cutting system to eliminate your specific pain points.